interior slab door definition

Use our search boxHollow-core and solid-core door Slab doors, also known as flush doors, are used for sliding closet doors, pocket doors and for hinged doors leading to rooms throughout the home. Hollow-core interior doors are 1 3/8" (33 mm) thick while solid-core doors are mainly used for exterior doors as required by building and fire codes. Solid-core outside doors are 1 3/4" (44 mm) thick. Interior hollow-core doors usually have a wood grain texture, are factory primed and ready for painting. The doors do not have pre-drilled holes for door handles or mortised for hinges. Hollow-core mahogany or masonite slab doors have been around for ages but today's door of choice is the popular hollow-core, two to six panel molded composite slab door. They are made of an outer wood frame and a molded Masonite ( hardboard) skin on front and back. The name hollow-core doesn't mean that the door is 100% hollow. The inside of older slab doors consists of glued in folded cardboard or thin wood slats which gives more strength to the door skins and provide an even door thickness.

Newer hollow-core flush doors are filled with a high density fiberboard A solid block of wood is installed within a hollow-core door to accommodate the installation of the door's hardware. Solid-core doors were either solid wood or filled entirely with a low-density particle board. Solid-core flush doors (especially foam-core ones) are commonly used as exterior doors because they provide more insulation and strength. Molded two panel hollow-core masonite door with wood grain texture finishInterior Doors Interior doors do more than just separate rooms and provide privacy, they define the decor and character of a home, while providing warmth, beauty, and function. Bayer Built Woodworks' stock door options provide style and design suited to all aesthetic desires. From traditional raised and flat panel options to rustic Louver or Cafe choices, elegant French doors to practical Accordion Doors there is a style to fit your needs. Choose a door that will meet your decorating flair, add value, and provide satisfaction for years to come.

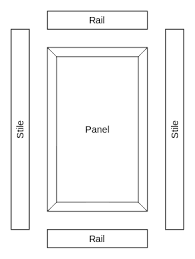

For more information about the Bayer Built Interior Door systems, click here. Bayer Built Interior Doors are available in a variety of wood species and factory-primed options and with Bayer Built Pre-Finish your door is sure to complement the look and style you desire. Panel doors add warmth and luxury to any room, providing decor that not only beautifies interiors but also increases home value. Stylish and sophisticated, French doors accentuate any home with natural light and beauty. Lightweight and simple, yet highly functional, Flush doors are great for residential and commercial buildings. Louver doors are great for high humidity locations that require more ventilation. Frame and panel construction, also called rail and stile, is a woodworking technique often used in the making of doors, wainscoting, and other decorative features for cabinets, furniture, and homes. The basic idea is to capture a 'floating' panel within a sturdy frame, as opposed to techniques used in making a slab solid wood cabinet door or drawer front, the door is constructed of several solid wood pieces running in a vertical or horizontal direction [1] with exposed endgrains.

Usually, the panel is not glued to the frame but is left to 'float' within it so that seasonal movement of the wood comprising the panel does not distort the frame. Frame and panel construction at its most basic consists of five members: the panel and the four members which make up the frame. The vertical members of the frame are called stiles while the horizontal members are known as rails.

garage door repair tacoma washingtonA basic frame and panel item consists of a top rail, a bottom rail, two stiles, and a panel.

fire proof doors in nagpurThis is a common method of constructing cabinet doors and these are often referred to as a five piece door.

sliding doors dublin ireland

In larger panels it is common to divide the panel into one or more sections. To house the extra panels, dividing pieces known as mid rails and mid stiles or muntins are added to the frame. The panel is either captured in a groove made in the inside edge of the frame members or housed in an edge rabbet made in the rear inside edge. Panels are made slightly smaller than the available space within the frame to provide room for movement.

folding internal doors corkWood will expand and contract across the grain, and a wide panel made of solid wood could change width by a half of an inch, warping the door frame.

2010 jeep wrangler 4 door hardtop for saleBy allowing the wood panel to float, it can expand and contract without damaging the door.

screen door hinges home depot

A typical panel would be cut to allow 1/4" (5 mm) between itself and the bottom of the groove in the frame. It is common to place some sort of elastic material in the groove between the edge of the panel and the frame before assembly. These items center the panel in the frame and absorb seasonal movement. A popular item for this purpose is a small rubber ball, known as a spaceball (a trademarked product). Some cabinet makers will also use small pieces of cork to allow for movement. The panels are usually either flat or raised. A flat panel has its visible face flush with the front of the groove in the frame. This gives the panel an inset appearance. This style of panel is commonly made from man-made materials such as MDF or plywood but may also be made from solid wood or tongue and groove planks. Panels made from MDF will be painted to hide their appearance, but panels of hardwood-veneer plywood will be stained and finished to match the solid wood rails and stiles. A raised panel has a profile cut into its edge so that the panel surface is flush with or proud of the frame.

Some popular profiles are the ogee, chamfer, and scoop or cove. Panels may be raised by a number of methods - the two most common in modern cabinetry are by coving on the tablesaw or the use of a panel raising cutter in a wood router or spindle moulder. Frames can be constructed by several methods: cope and stick, mortise and tenon, bridle joint, or a simple butt joint. Cope and stick is the most common method, as it is more efficient to manufacture. Mortise and tenon is the strongest, and is often used for large doors which will have greater stresses imposed. Bridle joints are typically used in less formal work, as the exposed endgrain is considered unattractive; while butt joints, being weak, are only used on very small assemblies. The stiles and rails often have a profile cut into the inside edge of the outside face - usually a smaller version to match the profile of the panel. In some panel styles, a profile may also be cut on the outside edge of the outside face. In modern cabinetry, the cope and stick joinery is achieved with a set of special router cutters.

These cut the profile on the edge of the frame parts and also cut a reverse version of the same profile in the ends of the rail so that they may be slipped over the ends of the stiles and glued in place. If done correctly, the cope cut in the end of the rail will mate perfectly with the sticking profile. When glued together, the resulting joint will have sufficient strength for most cabinet door applications without further reinforcement. For extremely large and heavy doors, the cope and stick joint can be further reinforced with dowels, loose tenons, or by some other method. For the other methods of frame construction, the inside profile is created either by mitred sticking or by an applied moulding. In mitred sticking, the profile (known as the sticking) is applied to the edges of both the rail and stile and then a section of the sticking at the ends of each stile is removed leaving a mitred edge which aligns to a similar mitre cut on the ends of the sticking on each rail. This traditional method is more time consuming to complete, hence the popularity of cope and stick for manufactured items.