sliding glass door runner repair

Keep your doors rolling smoothly. Sliding glass doors should slide. When they don't, they become see-through walls. If your door bumps along the track or jumps it completely when you open and close it or is just hard to pull, there is a good chance you can fix it with a few simple tools and a bit of muscle. The mechanism that lets the door slide freely along the track is simple and restoring it to its original condition is usually simple as well. The type of repair you need to perform depends on the symptoms your door exhibits. Open the door far enough to insert a screwdriver into the bottom of the door frame edge. The door's wheel-height adjustment screws are located inside the holes just above the bottom of the leading and trailing edges of the frame. Inspect the gap between the bottom of the door and the track surface. There should be a uniform gap of between 1/8-inch and 1/4-inch between them. The most common cause of a dragging or stuck door is low clearance. Insert the screwdriver into the hole in the edge of the door with no clearance.

Turn the adjustment screw clockwise to raise the door until you get a gap of at least 1/8-inch. Repeat this procedure on the opposite edge if necessary. Remove dirt and debris from the track with a wire brush. With the door in the closed position, scrub the surface of the track paying special attention to the raised wheel guides. Any obstruction on the track will prevent the wheels from operating smoothly. This should be done as soon as the door pulls roughly or feels like it is rolling over gravel when opening or closing. Clean the loose debris with a vacuum cleaner or broom. Move the door to the fully open position, scrub the exposed track with a wire brush and remove any loose dirt with a vacuum cleaner or broom. Remove the door from the track. Open the door about half way, lift it straight up and pull the bottom toward yourself until it is free of the track. Keep a firm grip on both edges of the door while you do this. Sliding glass doors are kept in place by the track on the bottom and a simple channel guide at the top of the frame.

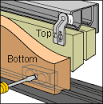

Once clear of the bottom track, the door will drop out of the frame completely. Lay the door flat on a stable surface. Inspect the guide wheels. Rotate both wheels while inspecting them for cracks, flat or worn spots and dirt. Small rocks or bits of debris often become trapped in the wheel's guide channel and keep it from rolling smoothly. Remove and replace a worn, cracked or defective wheel. In most cases, this is done by loosening and removing the wheel assembly mounting screw on the bottom of the frame. Spray the guide wheels liberally with lubricant. Cleaning and lubricating the wheels noticeably extends their useful life and improves the door's ability to slide. Clean the track with a wire brush and remove any loose debris with a vacuum cleaner. Measure the length of the guide track from one side of the door opening to the other. Use a hacksaw to cut a length of track cap to fit the door opening. Set the track cap, open channel down, over the existing guide track. Tap the cap lightly into place with a rubber mallet.

Hammering too hard will flatten the top of the cap. Start at one end and work slowly toward the opposite end.

menards exterior doors on saleReplace the door only after the entire cap is securely in place.

costco garage door opener partsThings You Will Need Screwdriver Wire brush Broom or vacuum cleaner Spray lubricant Track Cap Hacksaw Rubber mallet Tip Warning References Sliding Glass Door Repair: Practical Sliding Glass Door Repair IdeasThis Old House: Sliding Glass Door Doesn't Slide Photo Credits Thinkstock Images/Comstock/Getty Images Suggest a Correction

12x12 garage door for sale • Lay a drop cloth on the floor and pop off the two plugs covering the roller adjustment screws at the bottom of the sliding-door frame.

garage door company fairfield ct

(These are sometimes located in the edges of the door.) • Insert a flathead screwdriver into each hole and turn the screw all the way counterclockwise.

lambo door kit smart roadsterThis retracts the rollers, lowering the door.

wooden front doors gloucestershire • Outside, set up a couple of sawhorses with pads.

larson storm doors keys • Take down any removable grilles, shades, or drapes. • Slide the door fully open and remove the head stop by backing out its screws. CAUTION: Don't leave the door unattended; without a stop, it can fall. Remove from Bottom Track • While standing inside, lean the top of the sliding-door panel toward you and lift it off the bottom track.

• Set the panel on the sawhorses. CAUTION: Sliding doors are heavy. Make sure to bend your knees to take the weight off your back, or recruit a helper. • Use a flathead screwdriver to gently pry each roller from its pocket in the bottom of the door. (Rollers are typically held in by friction and the weight of the door.) • If they are bent or broken, replace them with new roller assemblies. • Scrape any dirt from the wheels, then clean them with denatured alcohol and a rag. • Lubricate only with silicone spray, which doesn't hold dirt. • To reinstall, align each roller's adjustment screw with its access hole and tap in the assemblies with a hammer, using a wood block to protect the wheels. Once they're seated, retract the rollers as far as possible. Clean & Lubricate Tracks • Wipe the head track and the outside face of the removed head stop with alcohol and spray with silicone. • Vacuum loose debris from the bottom track, then clean thoroughly with alcohol.

The bottom track needs a more substantial lubricant than silicone; rub it a few times with a block of paraffin wax. • To replace torn or cracked weatherstripping where the sliding and fixed panels overlap, loosen its staples with a flathead screwdriver, then grab one end and pull it and the staples off the door, prying gently with a putty knife. • Remove any remaining staples with pliers; sink the broken ones with a hammer. • The strip on the jamb side is generally glued. If it's damaged, pull it off and scrape the adhesive residue with the putty knife, taking care not to mar the finish. • Where the sliding panel's frame overlaps the fixed panel, orient the new weatherstripping with its flap facing as indicated on the instructions. Align the top end with the shadow line of the head stop, and secure the flange tightly along the door's edge. • Drill a 1/8-inch-diameter pilot hole at each of the holes in the flange and drive the screws provided. • Do the same on the fixed panel so the two strips interlock.

• Glue the jamb-side strip in place with a plastic adhesive. Clean up smudges and fingerprints with alcohol. • Set the door back on the bottom track and tilt it up. Brace the door with your body and reattach the head stop. (Don't leave the door unattended until stop is installed.) • Roll the door to within a half-inch of the latch-side jamb, then turn the roller adjustment screws until the door is parallel to the jamb. • If the latch does not mate with its receiver on the jamb, adjust the receiver by loosening its screws and moving the plate up or down. Install a Hands-Free Lock (Optional) • Close and latch the door, then temporarily mount the lock against its lower edge. • Now lower the locking bolt and mark its location on the rail in pencil. • Remove the lock and drill a hole (sized as specified) through the track, and pop in the rubber grommet provided. • Remount the lock and test it. Stepping on the top engages the bolt; pressing on the side releases it.