shower sliding door bottom seal

Shower Door Seal With Drip Rail Clear polycarbonate seals and edge wipes ensure that water stays in the shower without detracting from the clean style of the frameless shower. Manhattan Shower Door Sweep Sweep to fit standard Manhattan shower doors Grey Rubber flexible seal Double fin at bottom T Style Shower Seal For Framed Door Clear vinyl bottom seal 5/32" (4mm) Tee style For aluminum framed shower doors Polycarbonate U With Bulb Attachment The CRL Clear Polycarbonate 'U' with Bulb Attachment is a versatile seal that can be mounted to the edge of a door or panel for a variety of ins... Dual PVC Seal and Wipe Clear Dual Durometer PVC Seal and Wipe has two uses: Snap it on door bottom and the soft lip acts as a wipe or Snap it on an overlapping ... One Piece Bottom Rail with Clear Wipe Ultra clear One-Piece Bottom Rail is snapped on the bottom of the door to achieve a seal. Because it is a single-piece sweep, it means the vi...

Multi Purpose Strike Angle Jamb Multiple Uses for Versatility Commonly Used in 135 Degree Neo-Angle Applications This Clear Polycarbonate Strike Angle Jamb is used for both...

garage door installers milton keynes Polycarbonate Strike and Door Jamb for 180 Degrees This Clear 180 degree Polycarbonate Strike and Door H-Jamb with Vinyl Insert is snapped onto the fixed panel running inline with the door. Translucent Double Fin Seal can be used for inswing or outswing doors. The two different size fins allow the installer a choice of seal lengt... SDTB Bulb Seal is now available with pre-applied Hi-Bond Tape, for ease of installation. Simply peel back the thin tape lining to expose the... Translucent Silicone Bubble Seal Translucent Silicone Bulb Seal can be used on inswing or outswing doors to close gaps from 1/16" to 3/16" (1.6 to 5 mm).

Can be Used on Insw... Vinyl Edge "T" Wipe SDTW T-Wipe is now available with pre-applied Hi-Bond Tape, for ease of installation. Simply peel back the thin tape lining to expose the cl... Translucent 'V' Seal are used only on doors swinging one way to seal gaps from 3/16" to 1/4" (5 top 6 mm). Adhere 5/16" (8 mm) rigid leg to ... SDTL L-Seal is now available with pre-applied high-bond tape, for ease of installation. Simply peel back the thin tape lining to expose the c... Y Inline Gasket for 180 Degree Showers "Y" Inline Panel Seal is for use on 180 degree inline glass-to-glass applications Soft Vinyl Single Leg for Quieter Door Closure •Measure the width of the shower opening in at least three places: threshold, up to 5 feet, and halfway in between. •Any wall that's more than ½ inch out of vertical over 5 feet will need a matching filler strip so that the door can be made plumb. •From the point on the threshold where the door will pivot, measure the distance to bath fixtures or any other potential obstacles that an outswing door might hit.

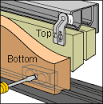

•Draw a sketch of the shower in plain view (looking down from above) and in elevation (side view). Fill in all the measurements and take it with you to the showroom. Click ''enlarge this image'' to view illustration labels. Cut the Base Track to Length Measure the length of the shower threshold, then use a hacksaw to cut the aluminum base track to fit tightly between the stall walls. Smooth the cut end with a file. Vacuum up the metal filings immediately so they don't scratch the bathroom floor or shower base. Set the Base Track Place the track on the threshold and use a tape measure to make sure that it's centered from front to back. With a pencil, mark the threshold along the edge of the track near each end. This allows easy repositioning if it slides around during installation of the jambs. Mark Position of the Hinge-Side Jamb On the side of the shower opening that will support the door, hold a jamb piece against the wall so that its lower end fits into the base track.

Without moving the track, use a 4-foot level to adjust the jamb until it's plumb. Stick a pencil through the jamb's screw holes to mark the wall. Remove the jamb, and at each pencil mark make a small divot using an automatic punch or hammer and nail set. (These tools chip the tile's glaze enough to prevent the drill bit from wandering.) Drill Holes for Wall Anchors Drill holes at each mark using a 3/16-inch-diameter masonry drill bit. Tap a plastic wall anchor into each screw hole. Use a plastic mallet to avoid marring the walls. Hold the jamb against the wall so its screw holes align with the plastic anchors. Drive a 1½-inch stainless steel pan-head screw into each hole. Lift the door with its attached hinge rail positioned to swing out, and slip the hinge rail into the jamb. Hold the door in place and check its strike-side edge with a level to make sure it's plumb. If it's not, pull the hinge rail out of the jamb slightly at the top or bottom.

Once the door is plumb, the hinge rail should still be engaged in the jamb—there's a full ½ inch of adjustment for plumb between these two pieces. While a helper holds the door in place, drill four 7/32-inch pilot holes through the holes in the hinge rail and into the mounted jamb. Fasten the hinge rail to the jamb with the ½-inch stainless steel pan-head screws provided. Install the Remaining Side Jamb If there is no glass side panel, slip the magnetic strike rail onto the remaining side jamb. Holding the rail and jamb, close the door until it lines up with the base track. Adjust the jamb until it's flush against the wall. Mark the wall alongside the jamb. Remove the jamb from the rail. Align the jamb with the pencil line and mark screw hole locations. Drill the holes for the plastic anchors. Screw the jamb to the wall. To install a glass side panel, slip the remaining jamb onto one of the panel's edges and the magnetic strike rail onto the other.

Fit the panel into the base track. Butt the jamb against the wall. Close the door and mark the wall along the jamb. Remove the jamb and the magnetic rail from the panel and attach the jamb. Slide the panel back into its jamb and base track. If a header is being used, measure and cut to length as in Step 2. Slip it over the top of the hinge jamb and side panel. Drill a 7/32-inch pilot hole through the inside face of the header at each end and into the corresponding jamb. Drive a ½-inch screw into each hole. Replace the magnetic strike rail on the strike jamb or, if used, on the edge of the stationary panel. Adjust it so that the magnetic strips on the door and rail produce a watertight seal along their entire length when the door is closed. Screw the strike rail into the holes of the strike jamb or stationary panel with the ½-inch screws. Screw Together the Frame Install the door handles that come with the kit. Align the outside door handle with the holes in the doorframe.

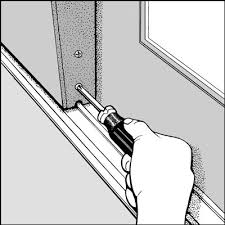

Attach the interior handle and tighten the setscrews. Stabilize the assembly by drilling a pilot hole and driving a ½-inch screw through the outside face of the base track wherever it meets a vertical frame member. Repeat the process on the inside face of the header. Center the screws on the aluminum extrusions to avoid hitting the glass. Pull the thin vinyl sweep out of the drip rail and set it aside. Cut the drip rail with a hacksaw to match the width of the door. Round off the ends of the cut with a file. Slide the vinyl sweep back into the groove in the rail. Crimp the ends of the groove closed with pliers to hold the sweep permanently in place. Trim off its overhanging end with a utility knife. With the vinyl sweep pointing down, hold the drip rail against the inside bottom edge of the door. Drill 7/32-inch pilot holes into the doorframe through the elongated mounting holes and low enough to avoid hitting the glass, which sits ¼ inch into the trim.