hollow metal door welding

Posted on August 15, 2015 Since the 40’s, technology has greatly improved how commercial hollow metal doors are made. The manufacturing process includes nine steps before a metal door is shipped out to be installed at a job site. First off, the process starts with the raw materials. The standard material for a commercial metal door is galvanealed steel. Galvanealed steel is a galvanized coating that has been annealed to make it easy to paint. First the doors go through a process called Shearing. This process cuts the sheet metal to the specified size needed for manufacturing. Next the steel door components are taken to a punch press. Once the material has been sheared it’s time to move on the Punch Press. The CNC Punch Press has 56 different tools used to make precision cuts for openings needed for metal door hardware, light kits, louvers and other accessories. After punching, the steel is taken to the forming press. This press is used to form the edges of the hollow metal doors by bending the steel along a hard edge.

This process uses a machine called a Press Break. A 300 ton press break is used with 2 stage forming dyes within the forming press to make sure there are tight crisp edges to every door giving it a precise fit within a hollow metal door frame. One of the most important parts of the metal door manufacturing process is called Spot welding. Spot Welding is used to attach hinge, closer and lock reinforcements within the body of the door, as well as securing any additional stiffeners. After the steel shell is assembled, a core is then added to the door. The core is used not only to provide a more rigid door, but also allows for additional features such as energy efficient door insulation, bullet resistance and sound proofing. There are three types of door cores: Honey Comb core, the steel stiffened core, and finally the polystyrene core. While in past the honeycomb core was most popular, environmental efficiency in modern buildings has demanded that a polystyrene core door become an industry standard.

Polystyrene offers a quiet, light weight fill with excellent insulation properties and is easily used in conjunction with steel stiffeners and other sound proofing. Special, rated polystyrene is also commonly used in fire rated metal doors because of it’s ability to withstand high temperatures and inhibit flame spread. Finally, after all the components of the door are assembled, the metal door is then placed through a machine called an edge welder. This automatic welder merges both of the edges of the two door halves into one finished product.

garage door opener rochester The next step is to move the door into the finishing room.

cheap shower enclosures torontoHere workers grind the edges of the weld down to a smooth finish, and make any finishing touches by sanding imperfections and stains.

car window repair redlands ca

The door is then inspected one last time for quality before being mounted to hangars and entering the painting booth. Hollow metal doors are typically painted with a baked on grey water based primer finish. This paint has a low voc, meets the lead free paint requirements, and is tested to meet the ansi spec 25010 for prime paints. This primer finish allows customers to easily paint the door to any desired color after it is installed. After finishing, the door is just about ready to be shipped off to the customer.

overhead door parts houstonThe last thing done before shipping is to label the door.

garage roller doors saThe label is used to inform installation crews, as well as building owners and codes inspectors’ important details about the door, materials and fire rating.

sliding door repair austin tx

Now the hollow metal door is complete, is packaged, stacked on a pallet and is ready to be shipped off. Watch for News and information These dedicated Resistance Welders are representative of the many affordable specialized machines developed and built by LORS for the Hollow Metal Door Industry since 1960. Gun Projection Welder, for welding hinge reinforcement to door panels on a horizontal plane. Eliminates need to stand door panel on its edge and increases productivity with only one operator. Six Gun End Channel Welder,Flat exterior weld dies provide improved weld appearance on cosmetic surfaces. Dual Gun Projection Welder, for welding hinge reinforcement to door panels. Similar in operation to Model 145 except straddles roller conveyor feed line. Welder, for welding hinge reinforcements onto metal door frames. fixture locates hinge reinforcement. Single Gun Projection Welder, for the welding of a lock box and/or hinge reinforcements onto a door panel.

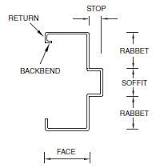

be employed as a low volume hinge reinforcement welder. Three Gun Door Frame Welder, welds corner gusset and pressure plate to door frame. Head Series-Type Resistance Welder, with through portal design set up to weld reinforcements onto metal panels, elevator and commercial doors. Projection Welder, welds four hinge reinforcements onto door frame. Features cascade sequence operation to minimize demand on the primary electrical service. Seam Welder, welds longitudinal seam edge on hollow metal doors. to skip openings for hinge reinforcements. more information and available models, refer to our catalog. Knock-down masonry, drywall and multi-use frames are available from CURRIES® in series, profile, face dimensions, gauges, and door opening sizes to fit most any need in the construction industry today. In addition, CURRIES and its distributors can modify and weld frames to expand the variety of frames available even further. Frame components used in the building of window walls, borrowed lites, transom frames, sidelites, and other custom configurations are available in an almost limitless array, allowing total design freedom in developing aesthetically pleasing, functional units as required by the demands of today's architecture.