garage door springs edmonton

The following instructions for converting your garage door to a high lift system are written for only the confident mechanic. The task is more complex than installing a garage door from start to finish. The average diy-er should not attempt this. These instructions apply only to the standard type of garage door pictured below. Your cable drums and cables should look similar to these. The next part beyond the end of the spring assembly is the cable drum. The drum is cast aluminum alloy 4" in diameter and 13" in circumference around the flat portion. Just beyond the cable drum is the end bearing plate. The cable unwraps off the back of the drum between the drum and the wall and travels down beside the door, inside the track brackets and behind the roller stems as shown. When converting from standard lift tracks to a high lift system, you will need: Most residential garage doors use less than 54" of high lift to fit in garages with ceilings that are 12' high or less. With assembly these high lift parts cost $200.00 plus the cost of the tracks, springs and extra shipping.

For example, if you are converting from extension springs to high lift track and torsion springs, you will also need additional hardware including the shaft, end bearing plates and the center support bracket. If you have a Clopay or Ideal EZ-Set torsion spring system you will need to convert to standard torsion hardware, which includes end bearing plates and the spring anchor bracket (or brackets if you have a coupled shaft on a wider door). A third type of door system needing additional parts is the Wayne Dalton Torquemaster torsion spring assembly. On these garage doors, the entire torsion assembly will need to be replaced with a new shaft, spring anchor bracket, and end bearing plates. Standard spring anchor bracket kits cost $7.50 and the end bearing plate kits cost $9.00. You can view other options and prices at our garage door bearings and plates page. If you need a shaft to convert to a high lift system, we recommend buying a shaft locally from a steel supply center or a steel scrap yard.

To fit standard garage door hardware you need a hollow 14 ga. tube with one inch outside diameter. A 16 ga. tube will work on a single car door weighing less than 150 pounds; we recommend 11 ga. or solid keyed shafts on doors weighing over 450 pounds. Shafts for 8' wide doors can be shipped by UPS; shafts for wider doors can also be shipped by UPS, but they need to be be cut in the middle and coupled, requiring a coupler and two spring anchor bracket kits for two springs. Converting your garage door to high lift is dangerous work. It is impossible to cover every dangerous situation you may encounter. The directions below hopefully will help guide you in safely converting your door to a high lift system, but there are no guarantees. Pay special attention to the warnings that appear in red. In summary, you need to supply us with the following information when you contact us for a price for a high lift conversion kit for your garage door: You'll also want to consider the wind of the spring if you have only one, and conversion from one to two springs if that becomes necessary.

In these instructions we replaced a single spring with another single spring that had the same wind. The customer had installed a pad up above and finished it with drywall. You will need to check the area above your header for studs or pads for mounting the spring anchor bracket, as well as the track angle that supports the track extension. Often additional framing will be necessary. In addition, we often recommend converting to two springs for high lift. If you are converting to two springs, or if you already have two springs, we recommend reviewing our instructions for replacing garage door springs. Pay particular attention to the wind of the springs. The winding cone with red paint on it is normally installed on the left side of the center support bracket, and the spring with black paint on the winding cone is installed on the right side of the bracket. As with our torsion spring replacement page and our torsion spring price lists we begin this tutorial with our sternest warning:

We hear from many mechanics who relish the excitement of a challenge like this. Probably more often than not they are professional people such as engineers, doctors or lawyers who need extra space for their Porsches or Lamborghinis. By the time they order the hardware from us, they have already ordered located the lift needed to raise their car into that empty space where their opener once was. I salute you men. I am working hard to help you do what you could have figured out yourself. Hopefully the information on this page will help you save at least one trip to the hardware store. You have my deepest respect and best wishes.- Dan MusickOwner, DDM Garage Doors got an overhead door project or problem, you’ve come to the right place. Residential, commercial, or industrial doorSales, service and parts. New construction, or replacements, we’ve been doing it all since 1985. Give us a call > > Wayne Dalton Garage Door Parts Wayne Dalton's Original Torquemaster system, pictured above, also called the Torquemaster One system, used special hardware compatable with Wayne Dalton's Torquemaster torsion springs.

The Original Torquemaster system pictured above was used with two Torquemaster torsion springs. From left to right, the parts included: left winding bracket, left counter, counter gear, drive gear, left cable drum, left winding cone, support bracket, right winding cone, right cable drum, drive gear, winding gear, right counter, and right winding bracket. As of 2012 Wayne Dalton stopped making many of the original Torquemaster One parts. The cable drums were replaced with the new drums that are backward compatible. Earlier springs had .721" inside diameters and the plastic cones for these are no longer made. If you are ordering new springs, the new steel cones will come installed in the ends of the springs; you do not need to order cones with your new springs. If you need a cone that is not on the list below, you will need to install a new spring with the .65" inside diameter and the steel winding cones. You cannot replace the plastic cones for .721" ID springs with with the steel cones for .65" ID springs;

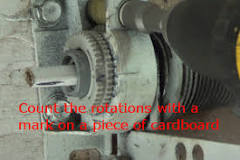

We are removing the plastic cones from our list below as inventories diminish. Counter wheels and counter gears have also been discontinued. If those are the only broken parts on your spring system, you can roll a piece of paper or cardboard and insert it into the end of your spring cone to count the number of turns as you wind the spring. In 2013 the factory ceased production of the Torquemaster I winding brackets and winding gears. Before purchasing replacement springs for the Torquemaster I system pictured above, check your winding brackets and your gears to make sure they are not stripped. If one of them is damaged, you will need to convert to a Torquemaster Plus system with new cable drums, cables and winding brackets pictured below. Instructions for replacing Torquemaster Plus springs are at Wayne Dalton's web site. You'll also need to replace the flagangles, or flag brackets as they are more commonly called in the door industry. These are designed to accommodate the Torquemaster Plus Type II winders.

Wayne Dalton makes two types of flagangles. The top bracket pictured above, our part number WD-FLGS, secures the tracks with screws. The bottom bracket above secures the tracks by twisting the flagangle tabs inside the tracks. This is our part number WD-FLGT. These parts, as well as kits for converting from Torquemaster One to Torquemaster Plus systems are available below. The cable drums pictured above replace the original cable drums that were designed by Wayne Dalton for the Original Torquemaster system. They work on both systems. The original drums had cable saftey covers, but these covers have since been obsoleted. Wayne Dalton also introduced the Torquemaster Plus system pictured above; it is also called the Torquemaster II system. The .721" ID oil tempered springs were replaced with .65" ID music wire springs. This system uses cable drums that are compatable with the Original Torquemaster system as well as the same bracket, but it uses fewer parts overall. The Torquemaster II system parts include, from left to right: winding bracket, left cable drum, left winding cone, support bracket, right winding cone, right cable drum, and right winding bracket.