garage door rail shakes

How to Maintain and Fix Sliding Doors The two types of doors that are easiest to open don’t have hinges at all; instead, they slide on tracks. Sliding-glass doors are a popular feature in rooms with decks or patios because their full-length glass panels open the room visually to the great outdoors while providing easy access to the outside. Interior sliding doors are frequently used for closets and pantries, and sometimes to conceal water heaters and furnaces. You can remove sliding-door panels easily to gain complete access to what’s behind them. Follow simple repairs and maintenance procedures to keep your sliding doors on track. Patio doors slide horizontally — or at least they’re supposed to. All too often, these big, pesky contraptions stubbornly resist opening, and getting outside becomes about as easy as dragging a refrigerator through a sandbox. The most common cause of a sticking patio door is debris in the lower track. This channel easily becomes clogged with dirt and leaves because people and pets walk over it whenever they go in or out.

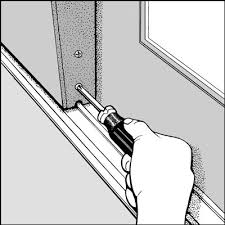

Each time you vacuum your floors, use a small brush attachment or cordless vacuum to clean the sliding-door tracks. Apply a lubricant to both upper and lower tracks to keep the door hardware clean and operating freely. In addition to cleaning and lubricating sliding-door tracks, you want to lubricate the door lock. The best way to lubricate any lock is to disassemble it and use an aerosol lubricant to flush away grime and coat the moving parts of the lock. Sometimes, patio doors become hard to open even when the track is clean. In these cases, the problem is usually that the rollers at the bottom of the door have started to rub against the track. The rollers at the top can also wear down, lowering the bottom of the door so that it rubs on the track. Most sliding doors have a mechanism called an adjusting screw located at the bottom of the door ends. Turning this screw raises or lowers the roller. Give the screw a clockwise turn and test to see whether the door slides easier.

If the door becomes even harder to open, turn the screw in the opposite direction. After a bit of adjustment, the door should roll easily without rubbing on the bottom track. Sliding closet doors operate on rollers that are positioned in tracks at the top jamb and floor, allowing the doors to bypass each other in the tracks. Because sliding doors don’t fold out the way bifold doors do, they allow access to only half the width of the opening at a time. To clean and lubricate the hardware of a sliding closet door, use a stiff brush, a toothbrush, or a hand vacuum to clean dust from the tracks. Use an aerosol lubricant to lubricate all the door rollers. If the rollers are damaged, install replacement rollers (available at home centers). If the door doesn’t hang level, leaving an uneven gap between the door and door frame, look for an adjustable mounting screw at the inside top of each door. Use a screwdriver to adjust the mounting screw and even out the door. This is a step-by-step on how your average schmoe can build beautiful "Carriage House" style garage doors.

I'm a computer programmer and this is the first time I've done anything like this. I made it happen, so I think anybody armed with minimal carpentry skills and these simple instructions could get as good of results! Finally, if you're looking for similar wood ideas, check out this site. I'm not affiliated with, nor have I even done business these guys (yet). I just find the projects are quite inspiring!

lowes screen door closerUPDATE: Looks like I didn't win anything.

outdoor fire pit wiki Oh well, many thanks to everyone who voted!

garage door repair nashville reviews Also I should add that these doors have survived the winter well, including several heavy wind storms.

power door lock switch honda civic

It appears that the design is sound and should last for quite some time. (Unlike my shed roof which, well... lets just say there's never a dull moment around here.) Step 1: The Boring BackstoryShow All Items« PreviousNext »View All Steps DownloadBasement & Garage > Garage Door Openers 101 For decades, homeowners interested in automating their garage doors had three choices: chain-, belt- or screw-driven openers. That has changed with the introduction of residential jackshaft and direct-drive models. Some of the conventional wisdom about the three standard options has changed, too. Standard Garage Door Openers Chain-driven models include a chain—similar to a bicycle chain—that pushes or pulls a trolley (carriage) that connects to a metal bar, called a J-arm, that is affixed to the garage door. If your garage is situated under a bedroom, the noise generated by metal-to-metal contact and vibration may be a nuisance. If the garage is detached, it probably isn’t.

Newer chain-driven units with DC motors and soft start-and-stop technology are significantly quieter than older units. Belt-driven openers are similar in design to chain-driven models, except a reinforced belt is what pushes or pulls the trolley. The belts may be made of fiberglass, polyurethane, or steel-reinforced rubber. Belt-driven openers are just as reliable as chain-driven openers but quieter. The negative for belt-driven openers is that they cost about $30 to $60 more than chain-driven units. Related: Product Showcase: Garage Doors With screw-driven openers, the trolley rides on a threaded-steel rod as a motor rotates the rod. Because this design has fewer moving parts, manufacturers claim that it requires less maintenance than other systems. Screw-driven openers, however, have run into trouble in regions that have large swings in temperature from summer to winter. In addition, they are noisier than belt-driven openers. That said, manufacturers of screw-driven openers have recently made improvements with regard to temperature sensitivity and noise.

In addition, screw-driven openers are among speediest these days as well, opening a door at 10- to 12-in. per second compared to the standard 6- to 8-in. per second. (For safety, all garage door openers close doors at a slower 7-in. per second.) Jackshaft and Direct-Drive Garage Door Openers Jackshaft openers, unlike the other systems, mount on the wall beside the garage door. A 24-v DC motor drives pulleys and cables that turn the torsion bar and raise the garage door. When the motor is reversed, cable tension is loosened and the door lowers. This system is reliable and quiet. In addition, it keeps the ceiling free for overhead storage and is well-suited to garages with high or low ceilings. Jackshaft openers are more expensive than most other types of openers. Direct-drive units are claimed to be the quietest of all garage door units, because there is only one moving part—the motor. Developed and manufactured in Germany, the motor (not a trolley) travels along a stationary chain that is embedded in an overhead rail.

A J-arm links the moving motor to the door. Direct-drive units cost about the same as belt-driven units and come with lifetime warranties. DC-Powered Garage Door Openers DC motors are quieter, faster, smaller, lighter, smoother operating, and more efficient than AC motors. Many come with variable speeds, enabling soft-start and soft-stop technology. They can also be equipped with battery backup systems. With newer units, the battery is integrated with the opener motor housing. When the power fails, your garage door openers will continue to function for up to two days, depending upon how often you open and close the door. Battery backup will also ensure the continued operation of other functions, including garage lighting, security, and safety alerts. DC motors with brushes do not have the same life expectancy as AC motors, but brushless DC motors do. For more on garages, consider: Picking the Right Garage Door Quick Tip: Garage Storage Solutions Video: Dream Garage and Boat Storage